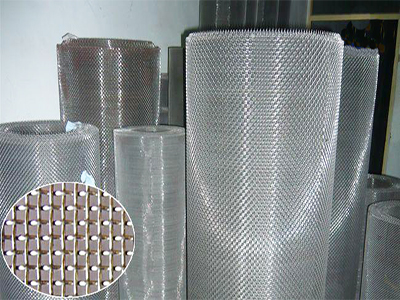

Titanium Mesh

Titanium harato:Titanium Mesh vita amin'ny tariby Titanium Alloys, ny orinasanay dia miray amin'ny orinasa Mesh manitatra ny vokatra isan-karazany amin'ny vokatra tariby sy ny vokatra vita.manana traikefa an-taonany maro amin'ny famokarana harato tariby, ary ny harato titane novokarina dia manana ny toetra mampiavaka ny fanivanana maharitra sy tsara.

• Karazana:

→ harato tenona tsotra → harato tenona

→ harato tenona efa nohanina → harato holandey

• Famaritana: 1 harato-100 harato

Ny fenitra ASTM dia arahina amin'ny famokarana tariby.Ny famaritana harato misy dia manomboka amin'ny tena mavesatra ka hatramin'ny tena tsara.Ny harato mavesatra indrindra dia vita amin'ny tariby 8.0mm raha ny harato tsara indrindra dia vita amin'ny tariby 0.03mm miaraka amin'ny 360mesh/inch.

• Fampiharana:Ny tariby titanium dia azo ampiasaina amin'ny sivana mahatohitra hafanana, fanamboaran-tsambo, famokarana miaramila, sivana simika, sivana mekanika, harato fiarovana elektromagnetika, sivana fanadiovana rano an-dranomasina, harato fitsaboana hafanana lafaoro elektrika, sivana solika, fanodinana sakafo, sivana ara-pitsaboana.

| Titanium Alloys Material Common Name | ||

| Gr1 | Sary UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | Sary UNS R56320 | Ti-3AL-2.5V |

| G11 | Sary UNS R52250 | Ti-0.15Pd |

| G12 | Ampahany R53400 | Ti-0.3Mo-0.8Ni |

| G16 | Sary UNS R52402 | Ti-0.05Pd |

| G23 | Sary UNS R56407 | Ti-6Al-4V ELI |

♦ Fikirakirana simika Titanium Alloys ♦

| kilasy | Famoronana simika, lanjan'ny isan-jato (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Elements hafa Max.SAMY | Elements hafa Max.sokajy | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum AlloyToetra ara-batana ♦

| kilasy | Toetra ara-batana | |||||

| Faharetana amin'ny sintona Min | Mamokatra hery Min (0,2%, offset) | Elongation amin'ny 4D Min (%) | Ny fampihenana ny faritra Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |